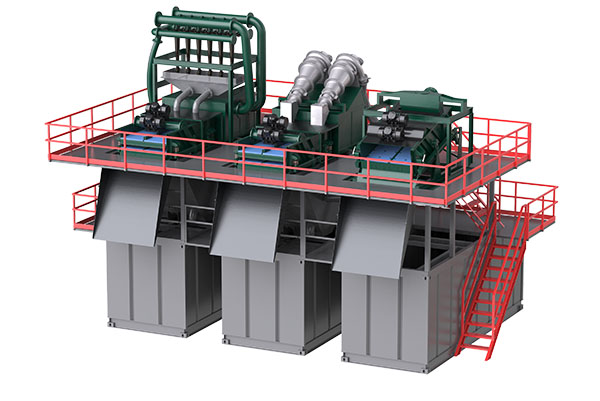

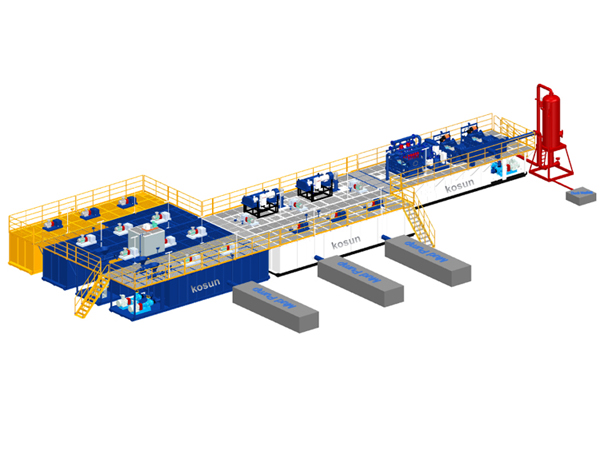

Drilling Waste Management SystemOil drilling fluid solids control system is widely used in oil gas drilling and workover as drilling fluid purification treatment equipment.It can separate the solid and liquid in the drilling fluid, recycling the drilling fluid, also known as mud purification system.blob.pngThe whole drilling fluid recycling system tanks and pits can be separated and connected to match the rig drilling work request.The system have 5 phase purification equipment, including shale shaker, vacuum degasser, desander

HDD Mud TreatmentKD Slurry treatment plant. slurry separation system, desander plant, desanding plant for Trenchless HDD,Shield,Pipe-jacking TBM,Pile foundation engineering,Underground continuous wall milling slot machine.

Solids Control Equipment and System

Drilling Dluid Waste Management

Fracturing Fluid & Anti-drainage Treatment

Oilfield Sludge Sewage Treatment

Trenchless (HDD) Mud Recycling System

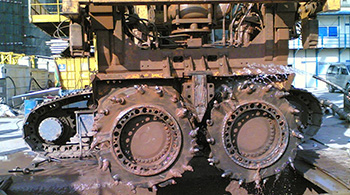

Shield&Pipe-jacking&TBM Slurry Separation System

Pile Foundation Engineering Slurry Treatment System

Underground Continuous Wall Desander Plant

KD-500 Desanding Plant

KD-200 Slurry Separation System

Slurry Treatment Plant, Separation Plant

KD-100 Slurry Treatment System

Drilling Mud Cleaner

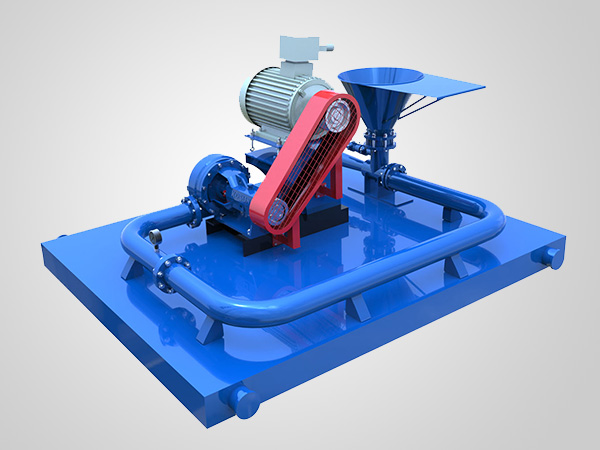

Jet Mud Mixer

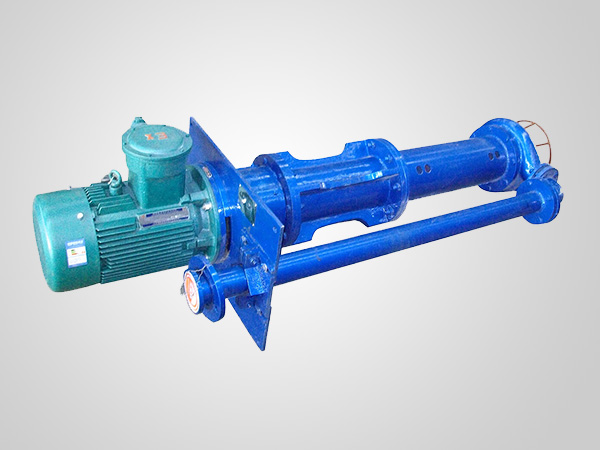

Submersible Slurry Pump

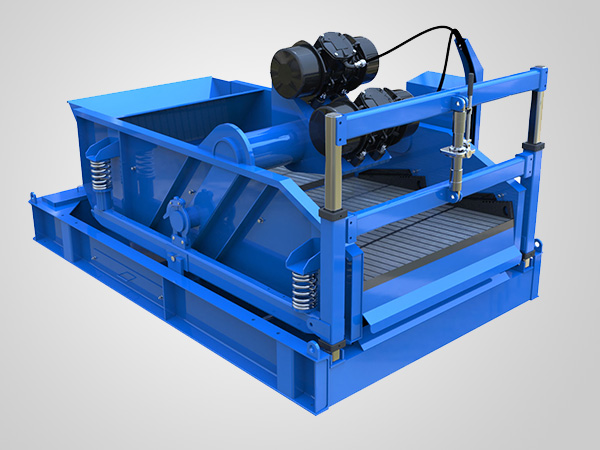

Linear Motion Shale Shaker

Balanced Elliptical Motion Shale Shaker

Mud Desilter

Mud Desander

Vacuum Degasser

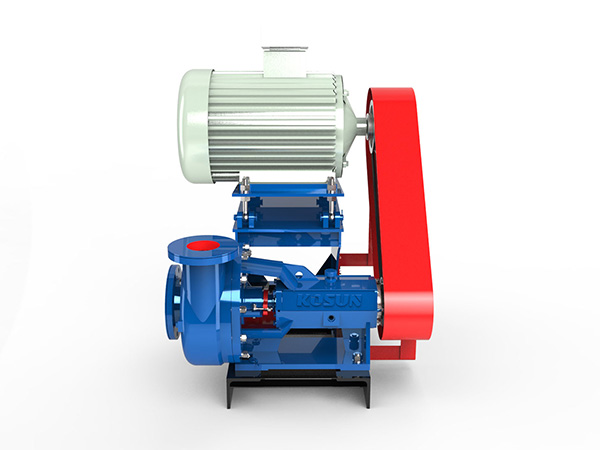

Shear Pump

D Series Decanter Centrifuge

DC Series Decanter Centrifuge

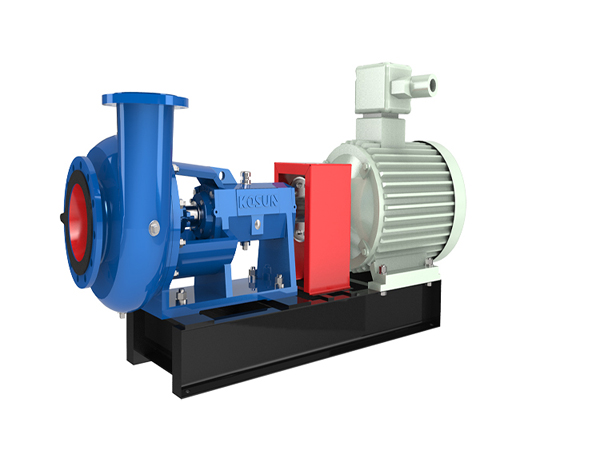

Centrifugal Pump

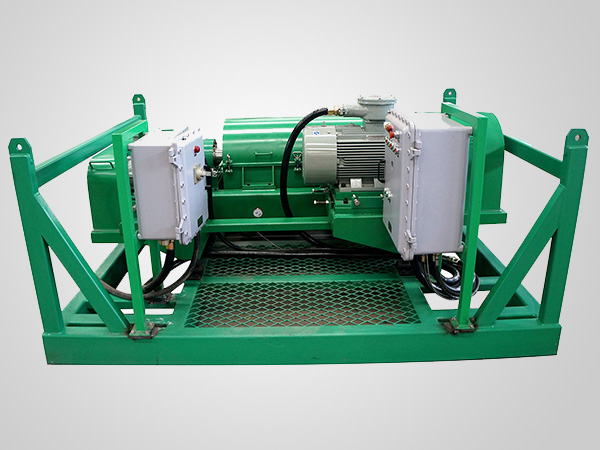

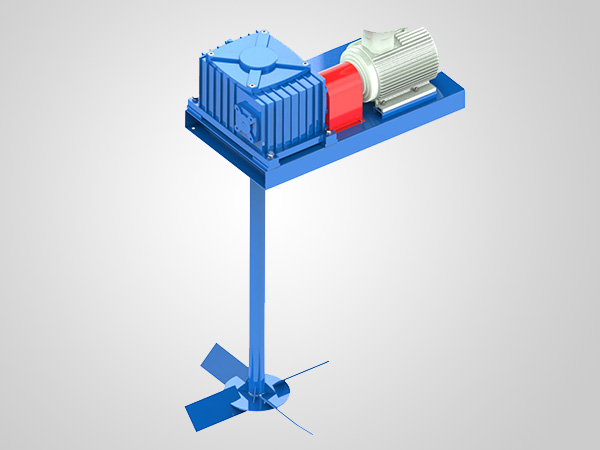

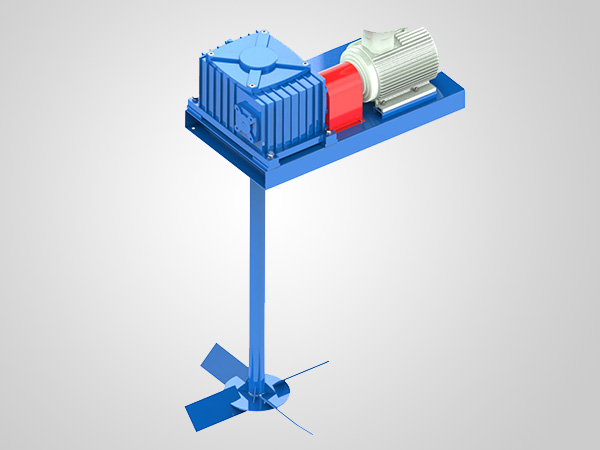

Mud Agitator

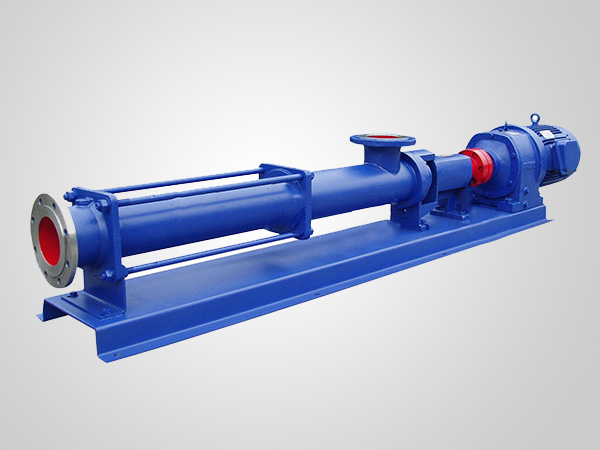

Screw Pump

Diesel tank

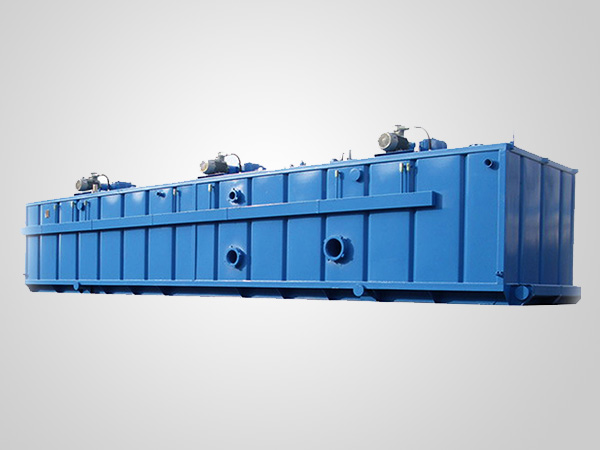

Drilling Mud Tank

Hydrocyclone

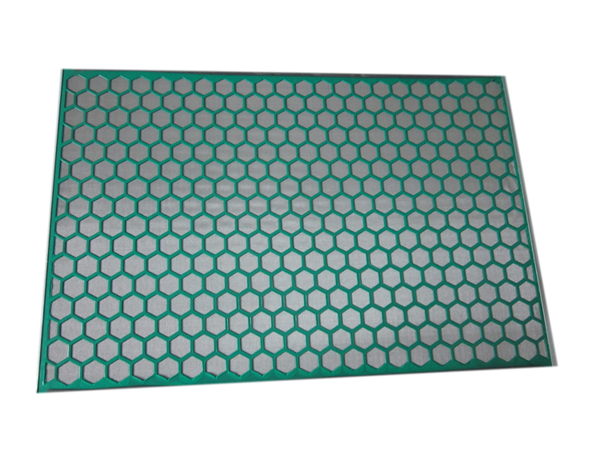

Shale Shaker Screen

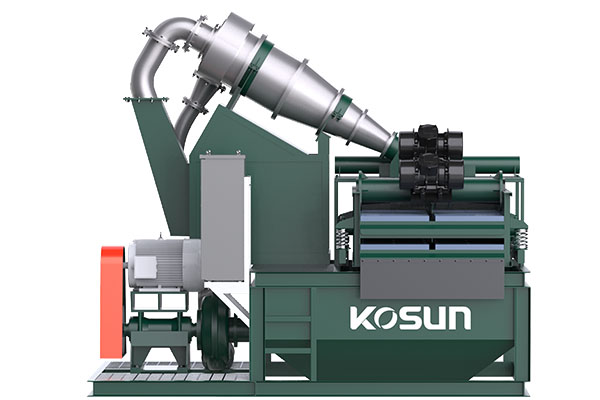

Hi G dryer

Mud Gas Separator,Poorboy Degasser

Mud Gun

Water tank

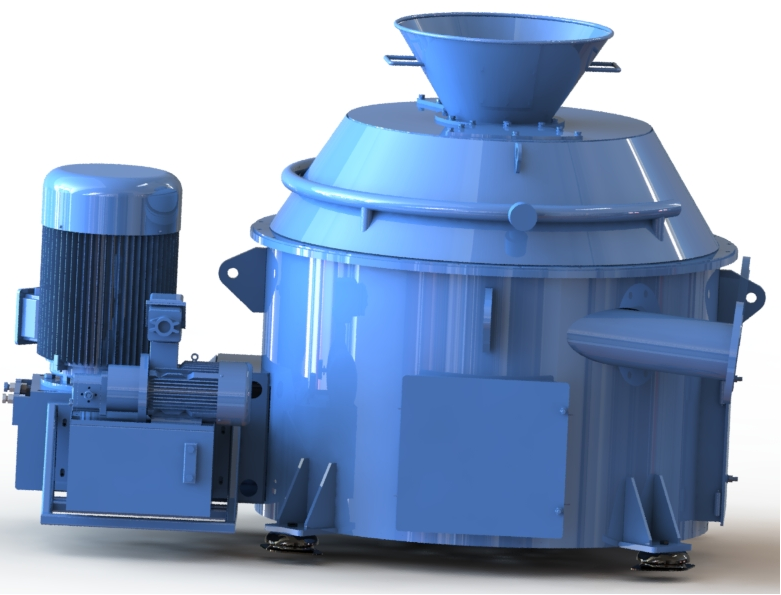

Vertical Cutting Dryer

D Series Decanter Centrifuge

DC Series Decanter Centrifuge

Mud Agitator

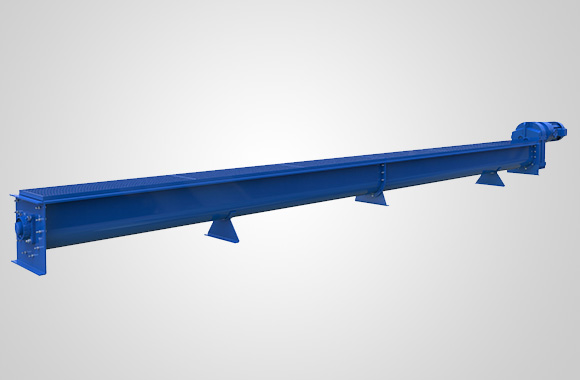

Screw Conveyor

Oil sludge treatment plant

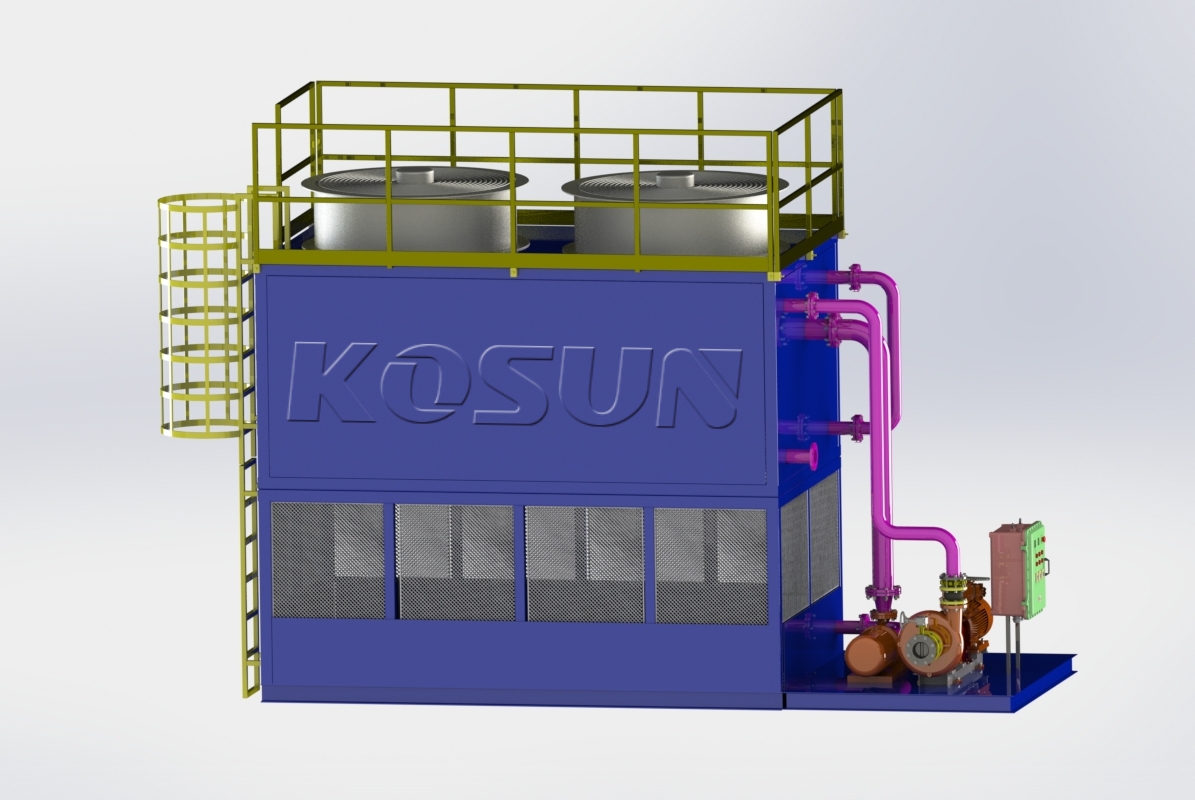

Mud (Drilling Fluid) Cooling System

Mud Cooling System

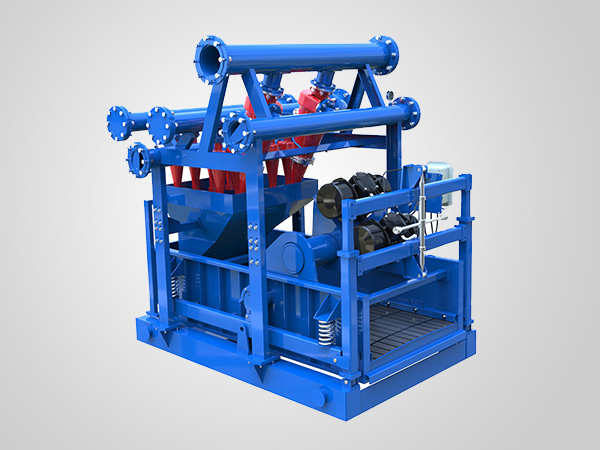

Drilling Mud Solids Control System

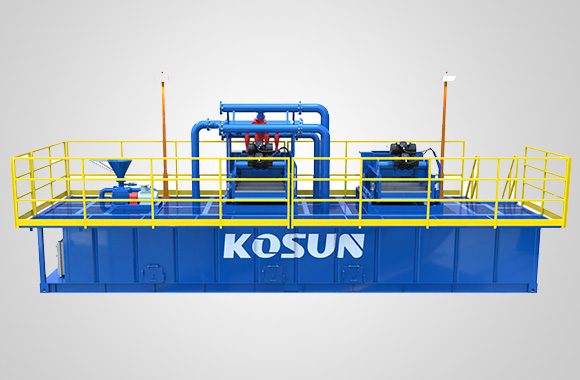

Mobile Solids Control System

Arctic Solids Control System

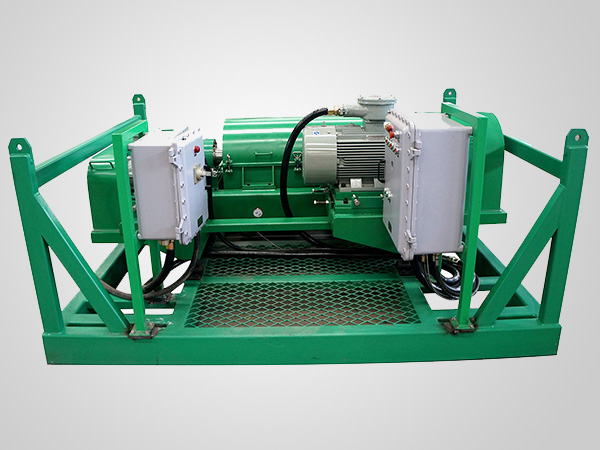

Skid-mounted Solids Control System

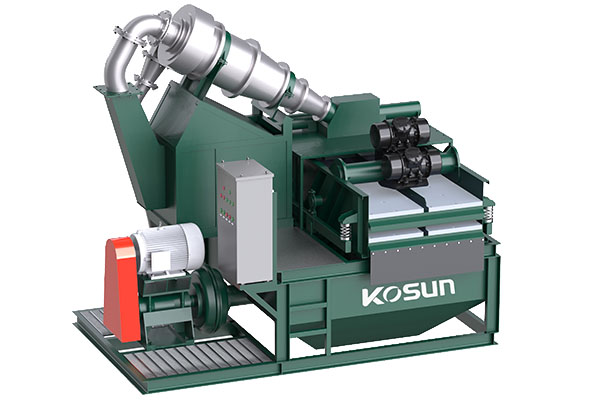

KOSUN High Speed Vertical Cuttings Dryer for Oil Based Cuttings TreatmentXi’an KOSUN has customized an oil-based drilling waste treatment system for international customers, which has been successfully put into use. This system is equipped with one LS305 screw conveyor, o...

How To Effectively Deal With Drilling Waste?KOSUN’s drilling waste treatment system refers to the harmless treatment of drilling waste from the wellhead before landing. The waste mud in the waste mud pool can also be diluted and then classifie...

Drilling Solid Control Equipment: Mud Agitators Sold to an Oman Oil Drilling Company8Pcs of mud agitators produced by Xi'an KOSUN has recently been successfully sold to an oil drilling company in Oman for drilling and solid control equipment....

Xi 'an KOSUN Mud Recycling System Treatment ProcessHDD mud recycling system is developed and produced by KOSUN to meet the requirements of non-excavation technology, used for purifying and treating mud returned from underground during horizontal direct...

Drilling Waste Management Equipment-Drilling Cuttings DryerThe drilling cuttings dryer, also known as a vertical centrifuge, is mainly composed of the following parts: scraper, screen basket, motor, oil pump, base, etc....

XI 'AN KOSUN INVITES YOU TO ATTEND THE OIL AND GAS EXHIBITION IN MOSCOW, RUSSIAXi 'an KOSUN invites you to attend the Oil and Gas Exhibition in Moscow, Russia...

Kazakhstan - Large oily sludge treatment projectAt the beginning of 2024, KOSUN Machinery successfully delivered an oily sludge treatment system to Kuwait. ...

Russia-ZJ30 Rig Solid Control SystemThe Russia-ZJ30 rig solid control system is capable of classifying and treating drilling mud. It can also perform mixing, degassing, weighting, and agitating of drilling mud, as well as supplying mud a...

KOSUN 1000HP Drilling rig solids control system case in North AfricaThe 1000HP Drilling rig solids control system consists of 4 mud tanks, a shale shaker, a vacuumdegasser,Desander, desilter, four-stage purification equipment, to meet the processing requirements of dri...

Tail slurry treatment system working case in IndiaTail slurry treatment system working site in India...

Solids control system working case in RussiaSolids control system working site in Russia...

KOSUN solids control equipment and drilling waste management equipment at a oil exploitation project KOSUN solids control equipment and drilling waste management equipment at a oil exploitation project in Argentina...