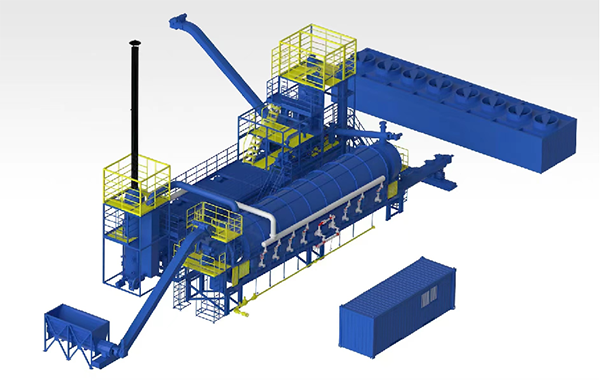

Introduction of continuous rotary thermal desorption equipment

Pub Date:Mar 21, 2023 | Views:86 |

The continuous rotary thermal desorption complete set of equipment adopts the principle of indirect heating and controlling the heating temperature and heating time to evaporate and pyrolyze organic matter under anaerobic conditions. The volatilization and decomposition of organic matter in the material are separated from the solid phase, so that The solid slag meets the harmless requirements, and the organic matter is converted into high value-added gas and oil products.

It is a new generation of thermal desorption equipment developed by our company. With the inclined rotary furnace body, the processing capacity, service life and maintenance cycle of the equipment are greatly improved.

Process flow of continuous rotary thermal desorption equipment

1, Solid Phase Process

After the raw material is pretreated, it is transported to the thermal desorption device through the feeding system. In the thermal desorption furnace, the temperature is raised to 400-600°C through indirect heating and maintained until the end of the reaction. Then it is discharged through the discharge system and cooled by the slag cooler. After that, it is transported to the discharge yard.

2, Gas phase treatment process

The mixed steam generated by the thermal desorption of raw materials is extracted by the induced draft fan, and the oil, ash, water mist and gas in it are removed through the washing tower and the gas-liquid separation device in turn, and then enters the burner through the non-condensable gas buffer tank. The nitrogen protection system provides nitrogen protection to prevent air from being mixed into the thermal desorption system and causing danger.

The natural gas is sent into the burner through the pipeline, and combusted with the combustion-supporting air, and the hot air generated enters the thermal desorption system for indirect heat exchange with the raw material, and the hot air after heat exchange and cooling is discharged to the atmosphere through the chimney.

3, Liquid phase treatment process

The oily sewage formed after spraying and washing will remove most of the floating oil through the degreasing system, and then the waste water will enter the follow-up device to remove suspended solids, enter the buffer water tank, and be lifted by the circulating pump to the cooling system to cool down, and then re-enter the washing tower as spray water . The floating oil collected and recovered by the oil storage system is pumped into the oil tank for storage and regular transportation. During the wastewater treatment process, the sludge deposited at the bottom of the equipment is discharged into the sludge sludge tank and transferred to the raw material yard for disposal at regular intervals.

Tags: continuous rotary thermal desorption equipment, continuous rotary thermal desorption complete set of equipment, suppliers, manufacturers, factory, wholesale, buy, price, quotation, bulk, for sale, companies, stock, cost.