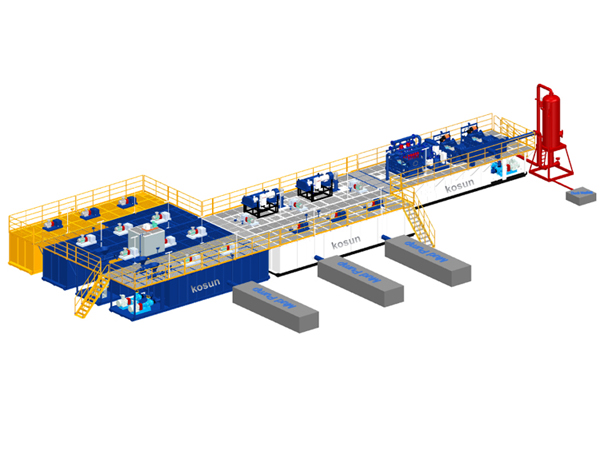

Drilling Waste Management SystemOil drilling fluid solids control system is widely used in oil gas drilling and workover as drilling fluid purification treatment equipment.It can separate the solid and liquid in the drilling fluid, recycling the drilling fluid, also known as mud purification system.blob.pngThe whole drilling fluid recycling system tanks and pits can be separated and connected to match the rig drilling work request.The system have 5 phase purification equipment, including shale shaker, vacuum degasser, desander

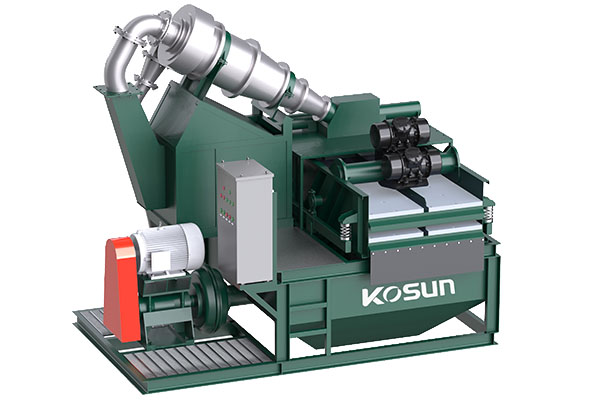

HDD Mud TreatmentKD Slurry treatment plant. slurry separation system, desander plant, desanding plant for Trenchless HDD,Shield,Pipe-jacking TBM,Pile foundation engineering,Underground continuous wall milling slot machine.

Solids Control Equipment and System

Drilling Dluid Waste Management

Fracturing Fluid & Anti-drainage Treatment

Oilfield Sludge Sewage Treatment

Trenchless (HDD) Mud Recycling System

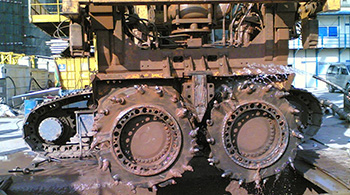

Shield&Pipe-jacking&TBM Slurry Separation System

Pile Foundation Engineering Slurry Treatment System

Underground Continuous Wall Desander Plant

KD-500 Desanding Plant

KD-200 Slurry Separation System

Slurry Treatment Plant, Separation Plant

KD-100 Slurry Treatment System

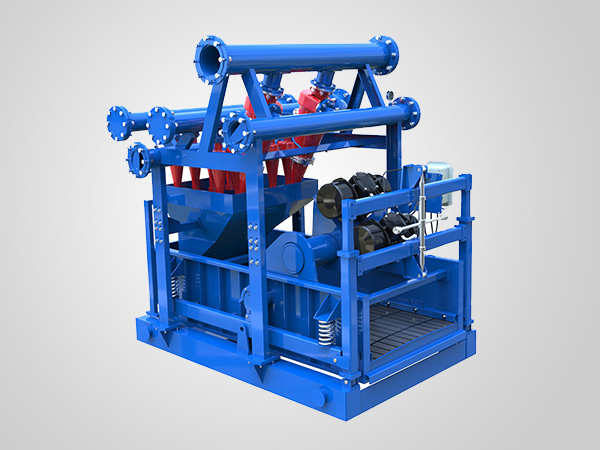

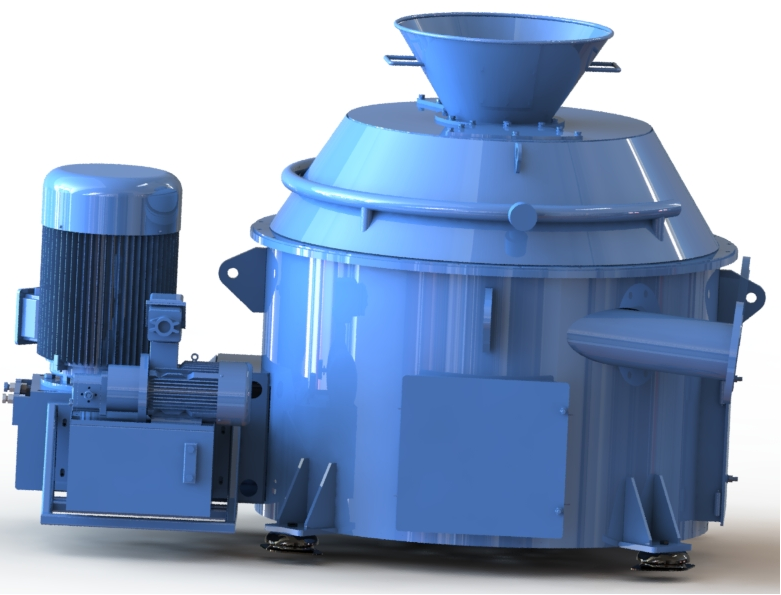

Dome-shaped mud cleaner

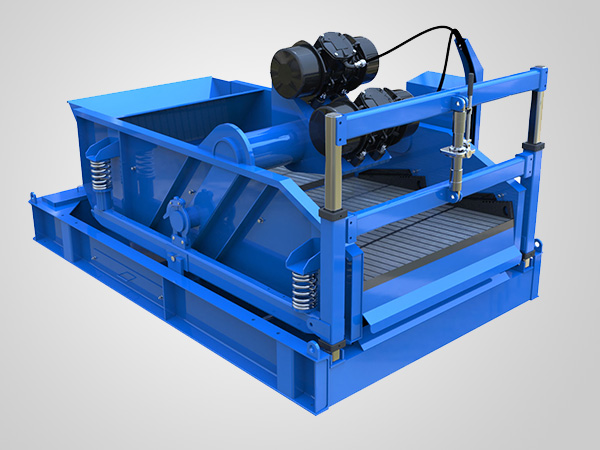

LS1850 Shale Shaker

LS606 Shale Shaker

KQG30 Automatic Tank Cleaning

Linear Motion Shale Shaker

Hi G dryer

DC Series Decanter Centrifuge

Drilling Mud Cleaner

MD300 vertical desander

Vacuum Degasser

Mud Gas Separator,Poorboy Degasser

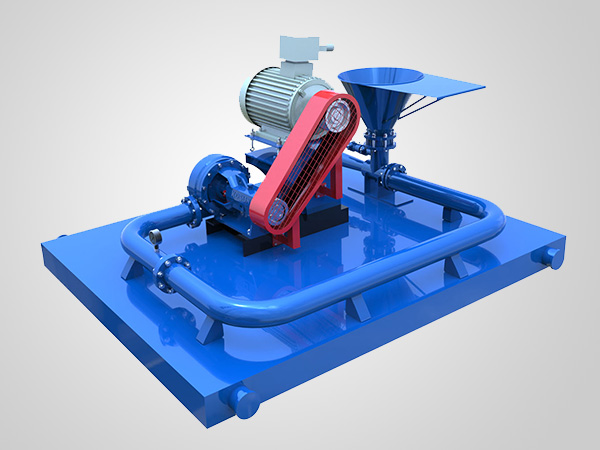

Jet Mud Mixer

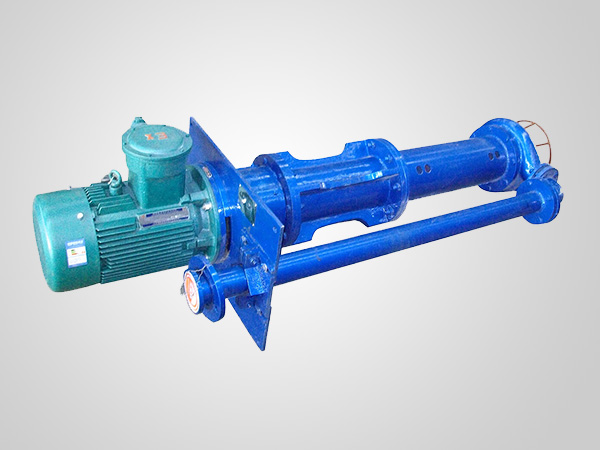

Submersible Slurry Pump

Balanced Elliptical Motion Shale Shaker

Mud Desilter

Mud Desander

Shear Pump

D Series Decanter Centrifuge

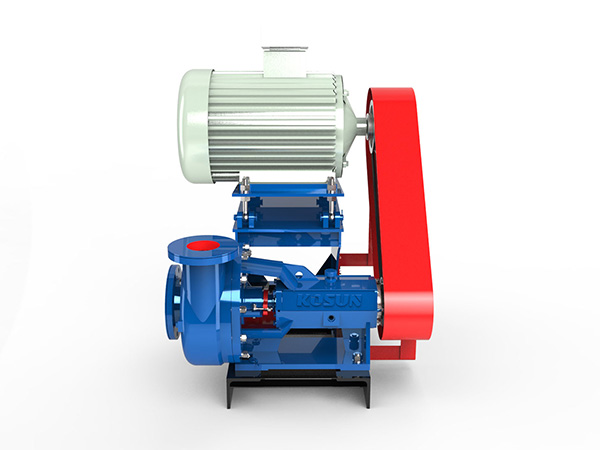

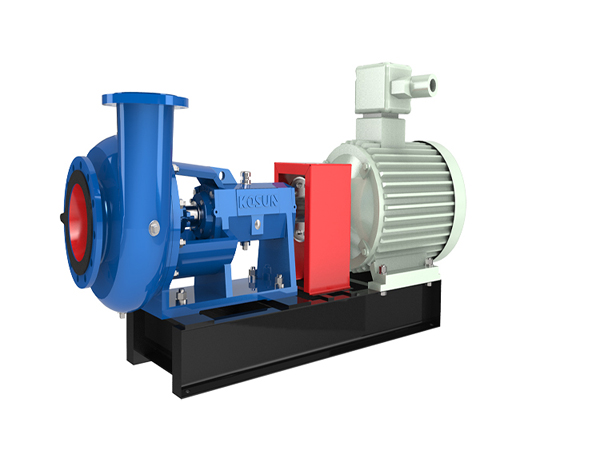

Centrifugal Pump

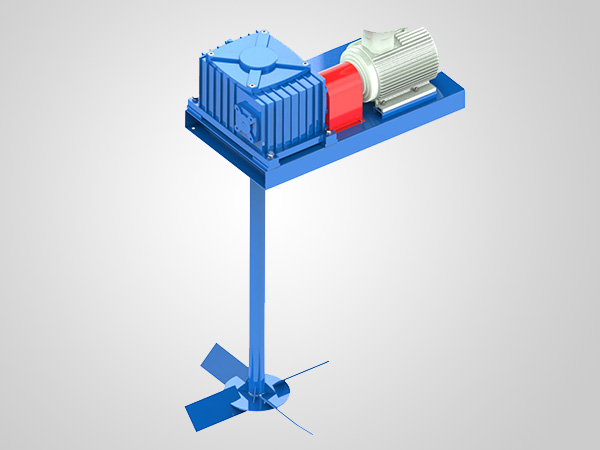

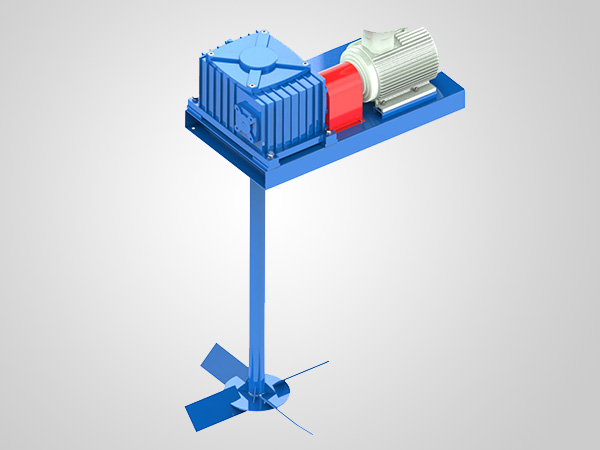

Mud Agitator

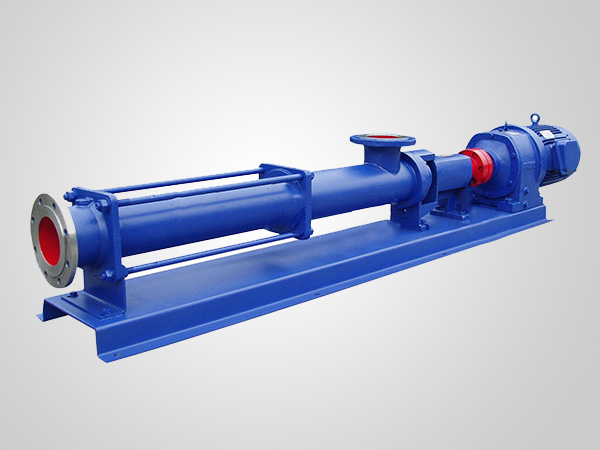

Screw Pump

Diesel tank

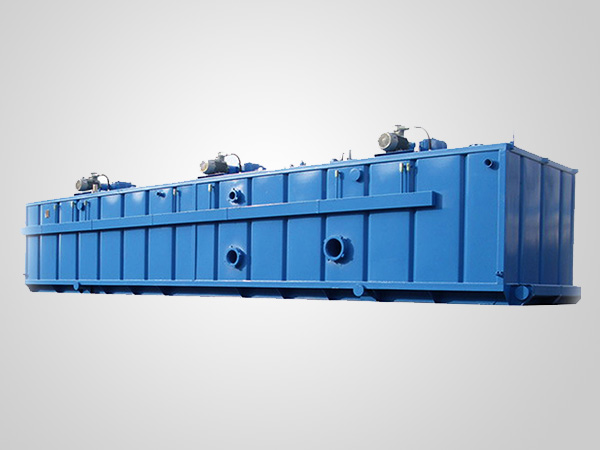

Drilling Mud Tank

Hydrocyclone

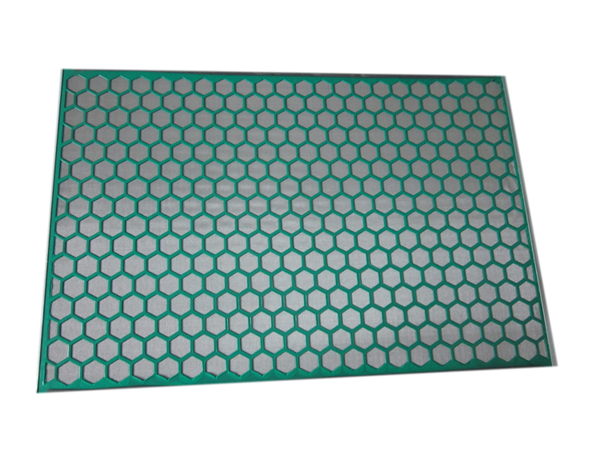

Shale Shaker Screen

Mud Gun

Water tank

sludge sand treatment

Vertical cyclone desilter

Oily sludge hot wash Processing system

The KFCQ300 vertical degasser

Vertical Cutting Dryer

DC Series Decanter Centrifuge

D Series Decanter Centrifuge

Mud Agitator

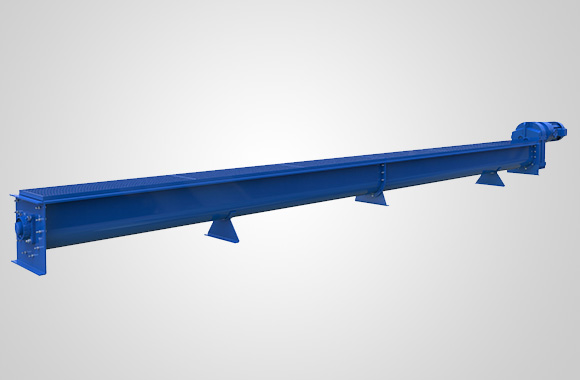

Screw Conveyor

Oil sludge treatment plant

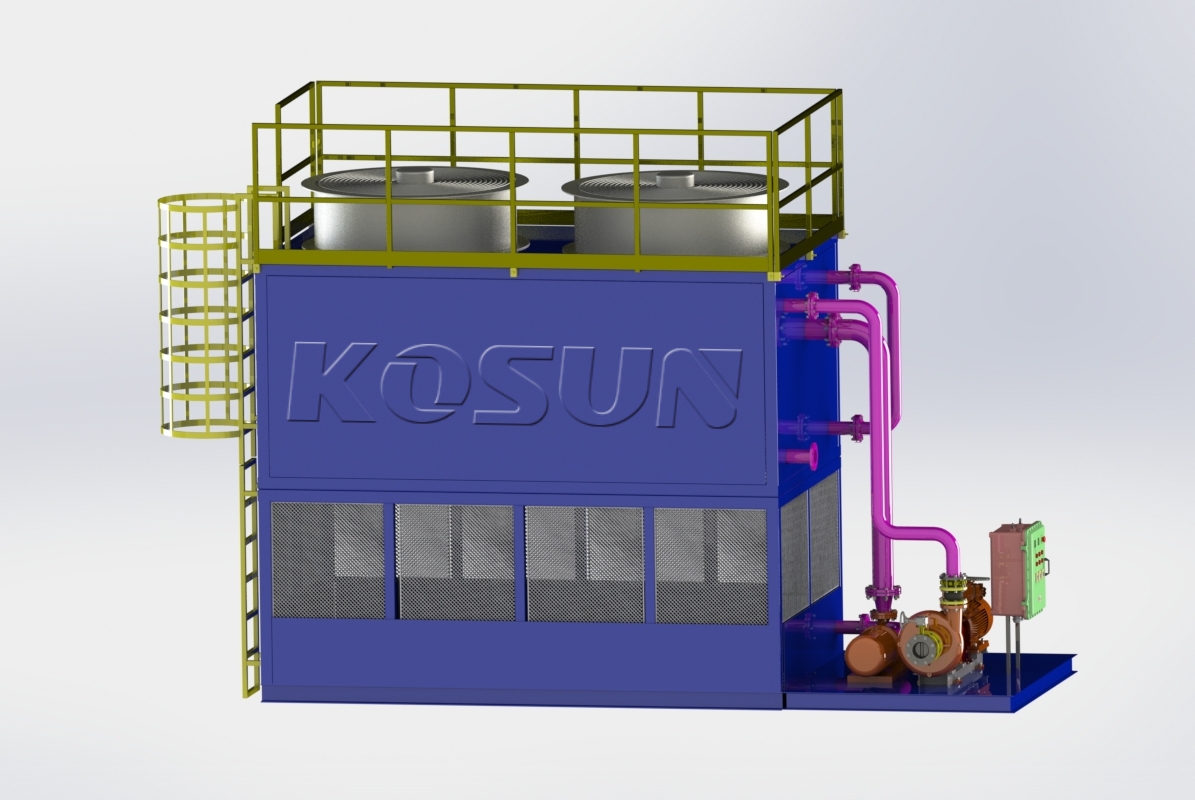

Mud (Drilling Fluid) Cooling System

Double track shaker

Mud Cooling System

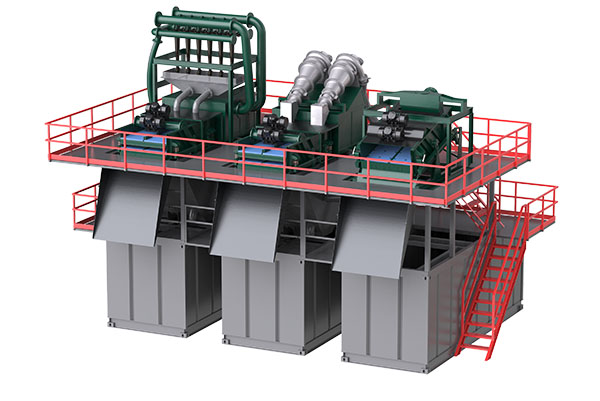

Drilling Mud Solids Control System

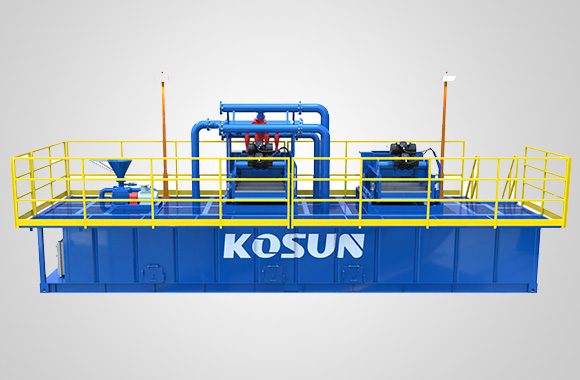

Mobile Solids Control System

Arctic Solids Control System

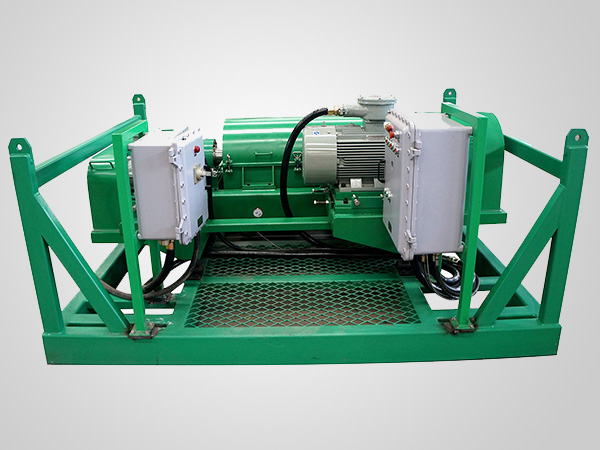

Skid-mounted Solids Control System

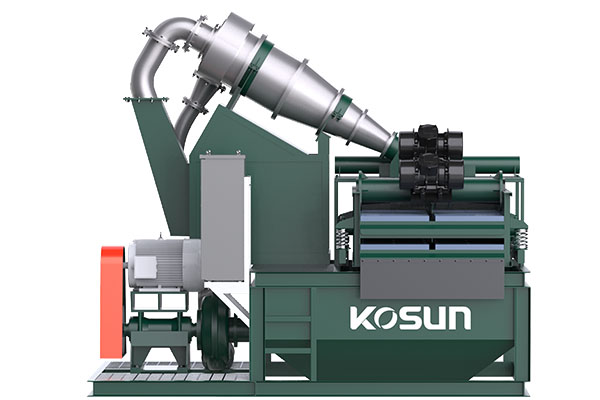

KOSUN Mud Treatment Station – Multidimensional Advantages for Sustainable DrillingThe KOSUN Mud Treatment Station integrates advanced technology and innovative solutions to deliver cost efficiency, environmental compliance, and operational safety , making it a critical infrastructur...

KOSUN screw pumps have been successfully dispatched to France, facilitating the efficient operation oRecently, a batch of high-performance screw pump equipment from Xi 'an KOSUN Machinery Manufacturing Co., Ltd. officially set off for France and will be applied to the local water well drilling proj...

Drilling Mud Centrifuge: Essential Equipment for Efficient Drilling OperationsIn the oil and gas industry, maintaining efficient drilling operations is crucial. One of the key pieces of equipment that ensures smooth drilling processes is the drilling mud centrifuge . This device...

Vertical Cyclone Desilter: An Efficient Solution for Solid-Liquid SeparationVertical Cyclone Desilter : An Efficient Solution for Solid-Liquid Separation Introduction The vertical cyclone desilter is a highly efficient solid-liquid separation device designed to remove fine slu...

Kosun Separation Drilling Cuttings Treatment SystemThe Kosun Separation Drilling Cuttings System is an advanced solution designed to efficiently separate and recover drilling fluids from drill cuttings while minimizing waste volume. This system signifi...

Advanced Oil Sludge Treatment Solutions by KOSUN: Maximizing Oil Recovery & Minimizing EnvironmenIn petroleum operations, oil sludge remains one of the most complex waste streams - containing recoverable hydrocarbons (10-50%), contaminated water (20-60%), and hazardous solids (20-50%). KOSUN Solid...

Large-scale ecological lake dredging and treatment projectLarge-scale ecological lake dredging and treatment project Project Background: The Xi an KOSUN Lake dredging and treatment system is designed to address issues such as sediment deposition and water qua...

KD-50 Trenchless sludge-water separation equipmentProject Case Introduction: Application of Russian KD-50 Trenchless sludge-water separation equipment Project Background: With the acceleration of urbanization in Russia and the in...

Kuwait - Landing Oil Sediment Treatment SystemProject Background: Kuwait, as a globally significant oil producer, generates a large amount of oily sludge during the process of crude oil extraction and transportation, posing a severe challen...

Solid control system of ZJ70 drilling rig in TurkmenistanProject Background: Turkmenistan, as an important energy producer in Central Asia, has extremely high requirements for the reliability and environmental friendliness of drilling equipment in the...

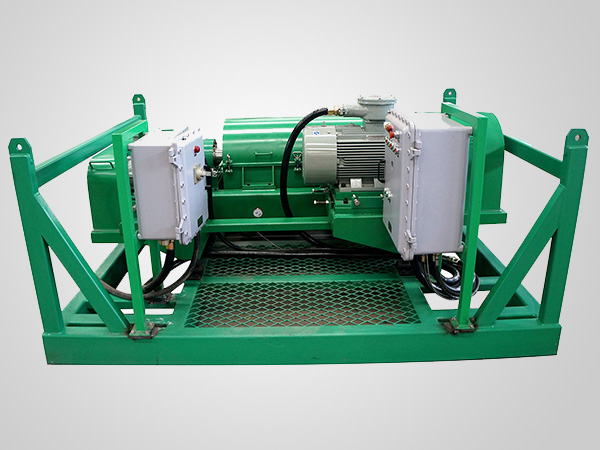

Skid-mounted double pump unit projectThe skid-mounted double pump produced by Xi 'an KOSUN is equipped with an independent diesel engine. The sand pump skid-mounted unit is composed of a generator set, two sand pumps and an inlet manifold...

9th World Oil and Gas Equipment Exhibition in Xi 'anThe 9th World Oil and Gas Equipment Expo will come to a successful conclusion at Xi an International Convention and Exhibition Center from November 7th to 9th, 2024. This exhibition has invited profess...