Construction Mud Recovery and Treatment in Horizontal Directional Drilling

Pub Date:Mar 19, 2025 | Views:147 |

Construction Mud Recovery and Treatment in Horizontal Directional Drilling (HDD) present unique challenges that require effective solutions. Managing the mud properly is essential to ensure environmental compliance and efficient drilling operations. In this article, we will discuss some strategies to solve the problems associated with the recovery and treatment of construction mud in HDD.

1, Mud Recovery Techniques:

a. Mud Pits and Sumps:

Implement mud pits or sumps at strategic locations along the drilling route to capture the construction mud. These containment areas allow for settling of the solids and sedimentation of the suspended particles, facilitating easier recovery and treatment of the mud.

b. Vacuum Excavation:

Utilize vacuum excavation techniques to remove the construction mud from the pit or sump. Vacuum trucks equipped with powerful suction systems can efficiently collect the mud, minimizing the risk of spills and contamination.

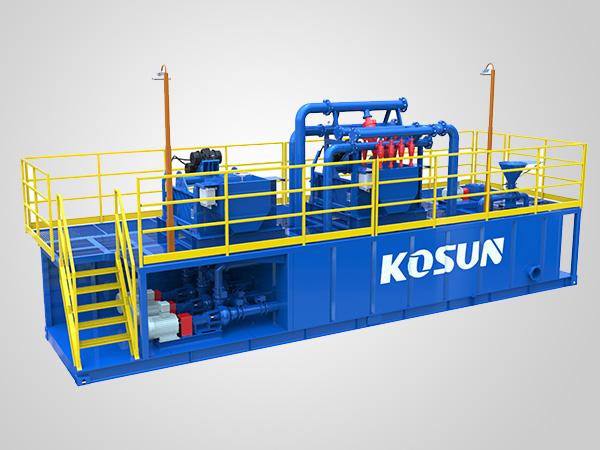

c. Solids Control Equipment:

Implement solids control equipment, such as shale shakers, desanders, and centrifuges, to separate and remove solids from the construction mud. This equipment plays a crucial role in recovering usable drilling fluid while minimizing waste generation.

2, Effective Treatment Methods:

a. Sedimentation:

Allow the construction mud to settle in a designated sedimentation tank or basin. This process helps separate the heavier solids from the liquid, enabling easier disposal or recycling of the clarified drilling fluid.

b. Filtration:

Pass the construction mud through various filtration systems, such as bag filters or filter presses, to remove fine particles and suspended solids. Filtration aids in improving the quality of the mud and minimizing environmental impact.

c. Chemical Treatment:

Consider the use of chemical additives to aid in the separation and treatment of construction mud. Chemical agents, such as flocculants and coagulants, can enhance solid-liquid separation, enabling easier removal of solids and improving the clarity of the drilling fluid.

3, Recycling and Reuse:

a. Dewatering:

Implement dewatering techniques, such as centrifuges or mechanical presses, to remove excess water from the construction mud. This process reduces the volume of waste generated and allows for the reuse of the drilling fluid.

b. Reconditioning:

Treat the recovered mud by adjusting its properties to meet the required specifications for reuse. This may involve adjusting the viscosity, pH, or adding specific additives to optimize the mud for subsequent drilling operations.

4, Environmental Considerations:

a. Regulatory Compliance:

Ensure compliance with local environmental regulations and permits governing the recovery and treatment of construction mud. Stay updated with the latest guidelines and requirements to avoid any legal or environmental issues.

b. Spill Prevention:

Implement spill prevention measures, including proper containment systems, spill kits, and trained personnel. Adequate containment and immediate response protocols can help minimize the risk of spills and prevent environmental contamination.

c. Waste Disposal:

Dispose of any residual waste or non-recoverable mud in authorized waste disposal facilities that comply with environmental regulations. Maintain proper documentation and tracking of waste disposal to demonstrate adherence to best practices.

Effectively solving the problems associated with the recovery and treatment of construction mud in HDD requires a combination of proper recovery techniques, effective treatment methods, recycling and reuse strategies, and strict adherence to environmental regulations. By implementing these solutions, companies can mitigate environmental risks, optimize drilling operations, and contribute to sustainable practices in the construction industry. It is essential to stay updated on the latest technologies and best practices to ensure the most efficient and responsible management of construction mud in HDD projects.

Tags: Construction Mud Recovery in HDD, Construction Mud Treatment in HDD, Construction Mud Recovery and Treatment in HDD, Mud Recovery and Treatment in Horizontal Directional Drilling, suppliers, manufacturers, factory, wholesale, buy, price, quotation, bulk, for sale, companies, stock, cost.

Related Products:

https://www.kosuneco.com/category-83.html