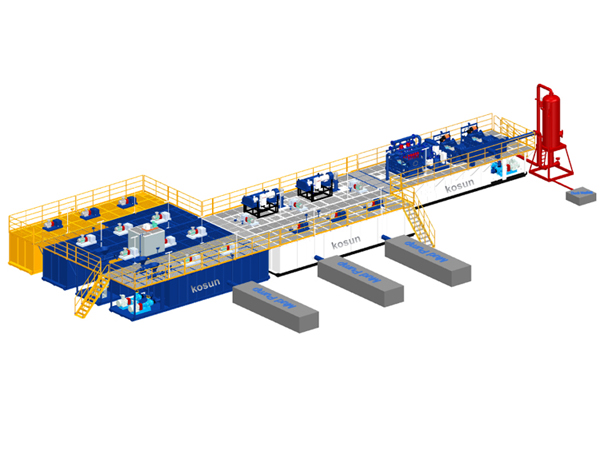

Drilling Waste Management SystemOil drilling fluid solids control system is widely used in oil gas drilling and workover as drilling fluid purification treatment equipment.It can separate the solid and liquid in the drilling fluid, recycling the drilling fluid, also known as mud purification system.blob.pngThe whole drilling fluid recycling system tanks and pits can be separated and connected to match the rig drilling work request.The system have 5 phase purification equipment, including shale shaker, vacuum degasser, desander

HDD Mud TreatmentKD Slurry treatment plant. slurry separation system, desander plant, desanding plant for Trenchless HDD,Shield,Pipe-jacking TBM,Pile foundation engineering,Underground continuous wall milling slot machine.

Solids Control Equipment and System

Drilling Fluid Waste Management

Fracturing Fluid & Anti-drainage Treatment

Oilfield Sludge Sewage Treatment

Trenchless (HDD) Mud Recycling System

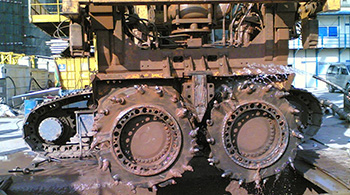

Shield&Pipe-jacking&TBM Slurry Separation System

Pile Foundation Engineering Slurry Treatment System

Underground Continuous Wall Desander Plant

Slurry Treatment Plant, Separation Plant

KD-100 Slurry Separation System

KD-50 Slurry Treatment System

KD-200 Slurry Separation System

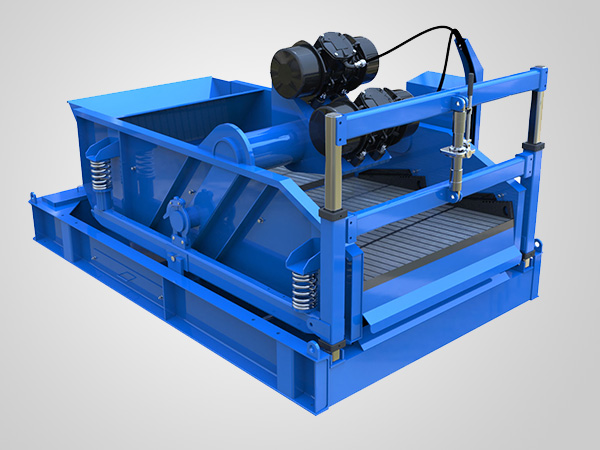

LS585 Shake Shaker

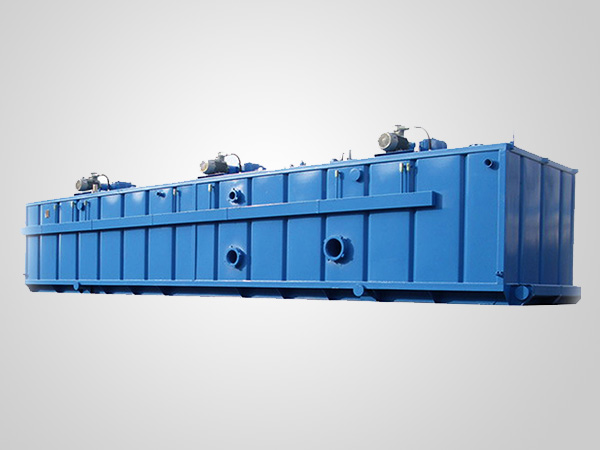

Drilling Mud Tank

DC Series Decanter Centrifuge

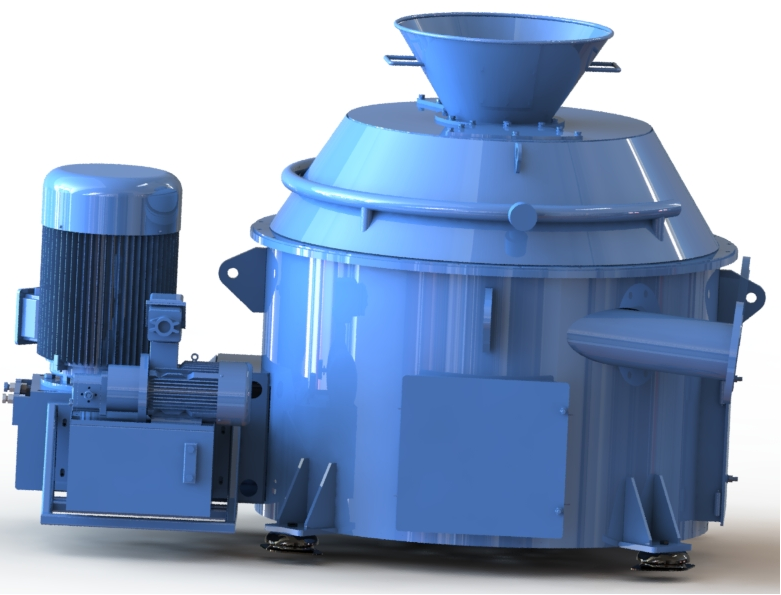

Dome-shaped mud cleaner

LS1850 Shale Shaker

LS606 Shale Shaker

KQG30 Automatic Tank Cleaning

Linear Motion Shale Shaker

Hi G dryer

Drilling Mud Cleaner

MD300 vertical desander

Vacuum Degasser

Mud Gas Separator,Poorboy Degasser

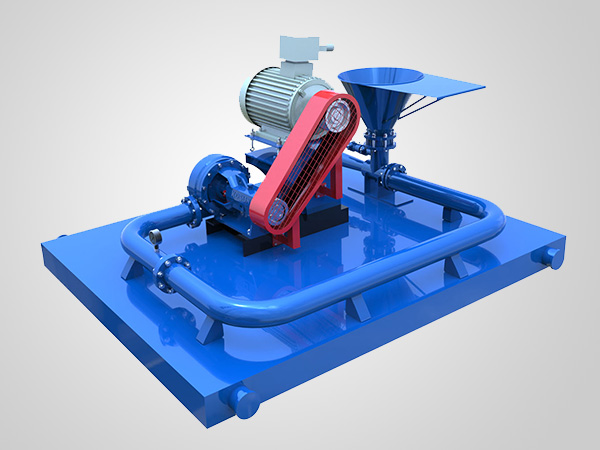

Jet Mud Mixer

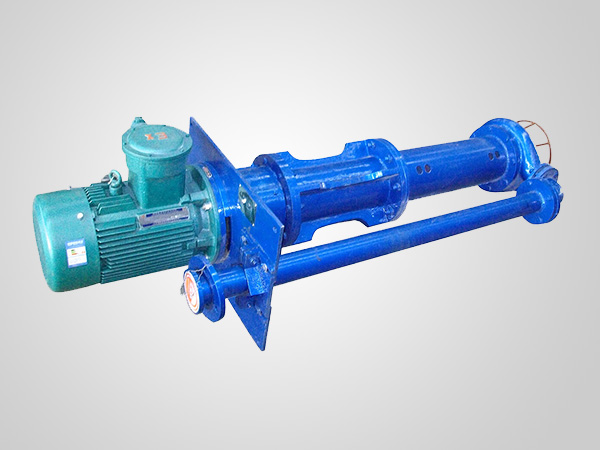

Submersible Slurry Pump

Balanced Elliptical Motion Shale Shaker

Mud Desilter

Mud Desander

Shear Pump

D Series Decanter Centrifuge

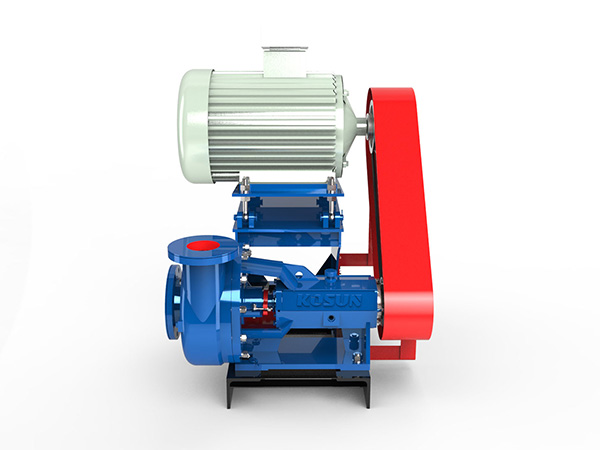

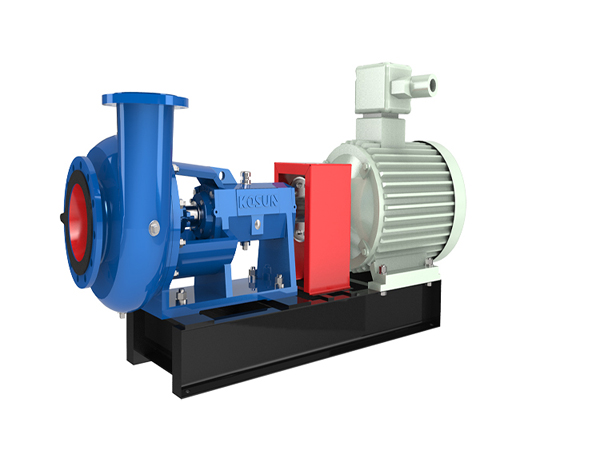

Centrifugal Pump

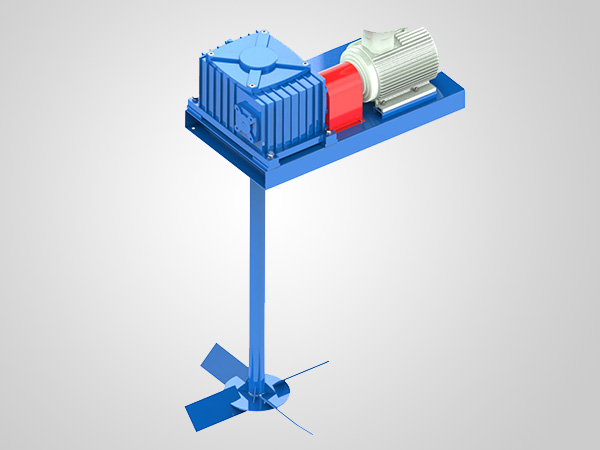

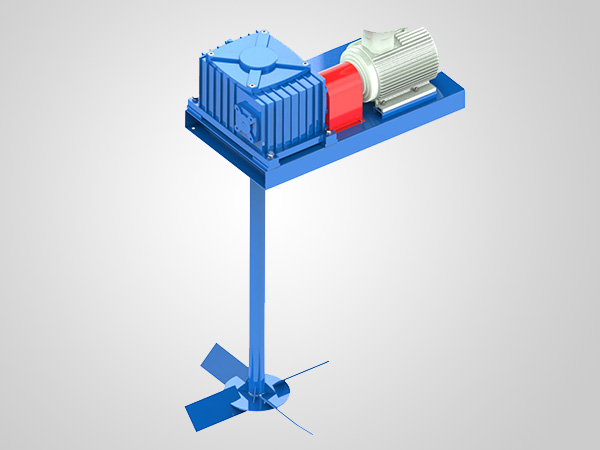

Mud Agitator

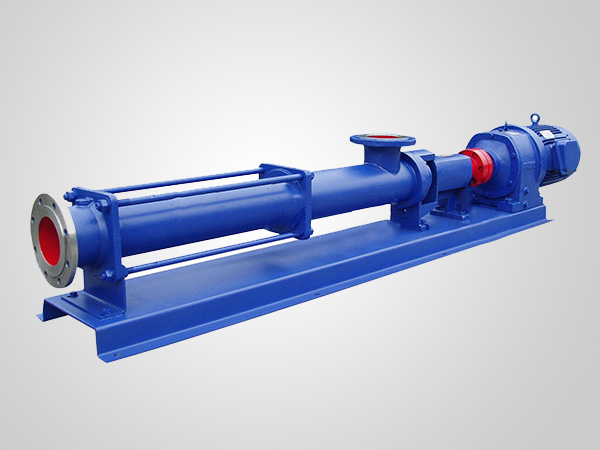

Screw Pump

Diesel tank

Hydrocyclone

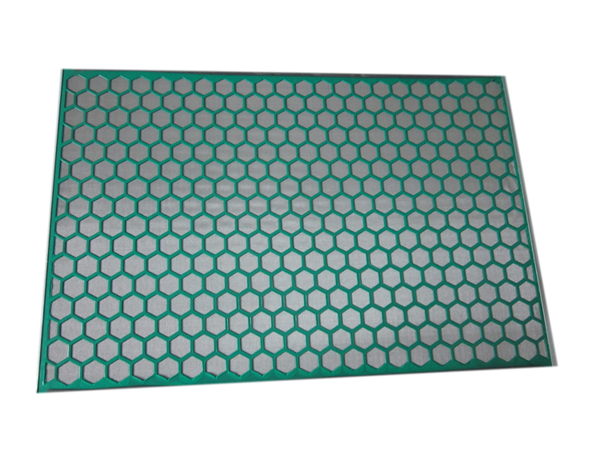

Shale Shaker Screen

Mud Gun

Water tank

sludge sand treatment

Oily sludge hot wash Processing system

1m³/h Oily Sludge Treatment System

DC Series Decanter Centrifuge

Vertical Cutting Dryer

Vertical cyclone desilter

The KFCQ300 vertical degasser

D Series Decanter Centrifuge

Mud Agitator

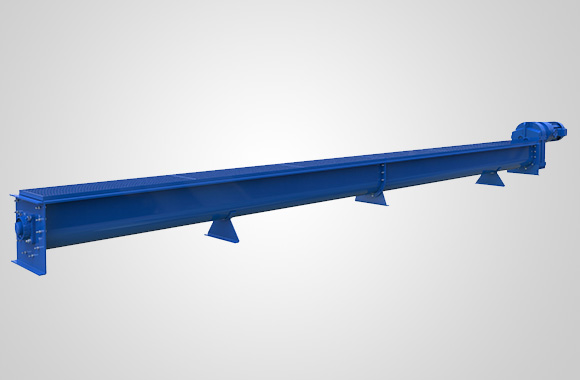

Screw Conveyor

Oil sludge treatment plant

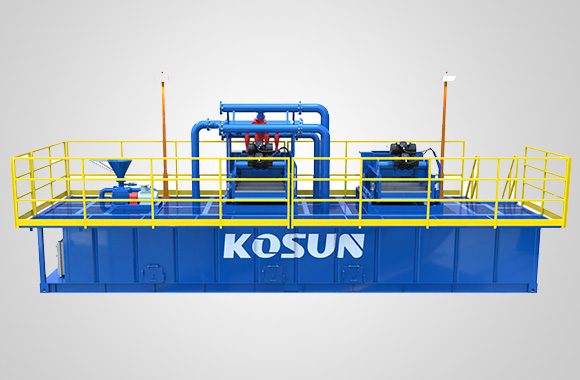

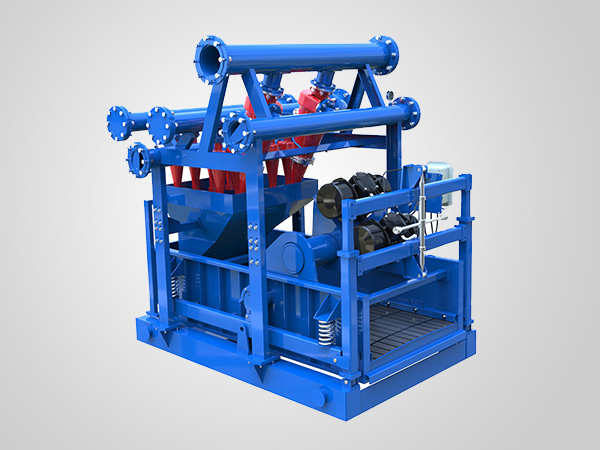

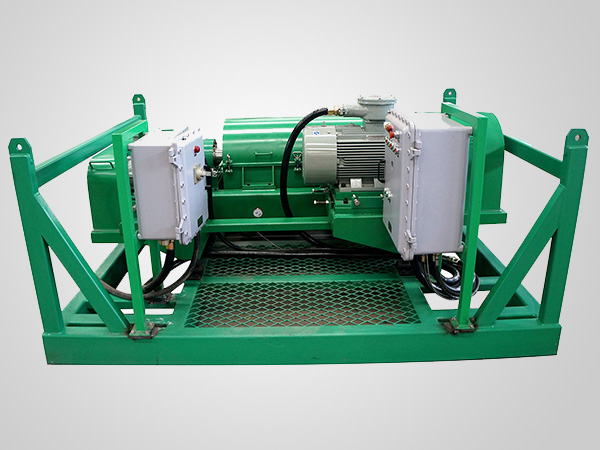

Mobile Solids Control System

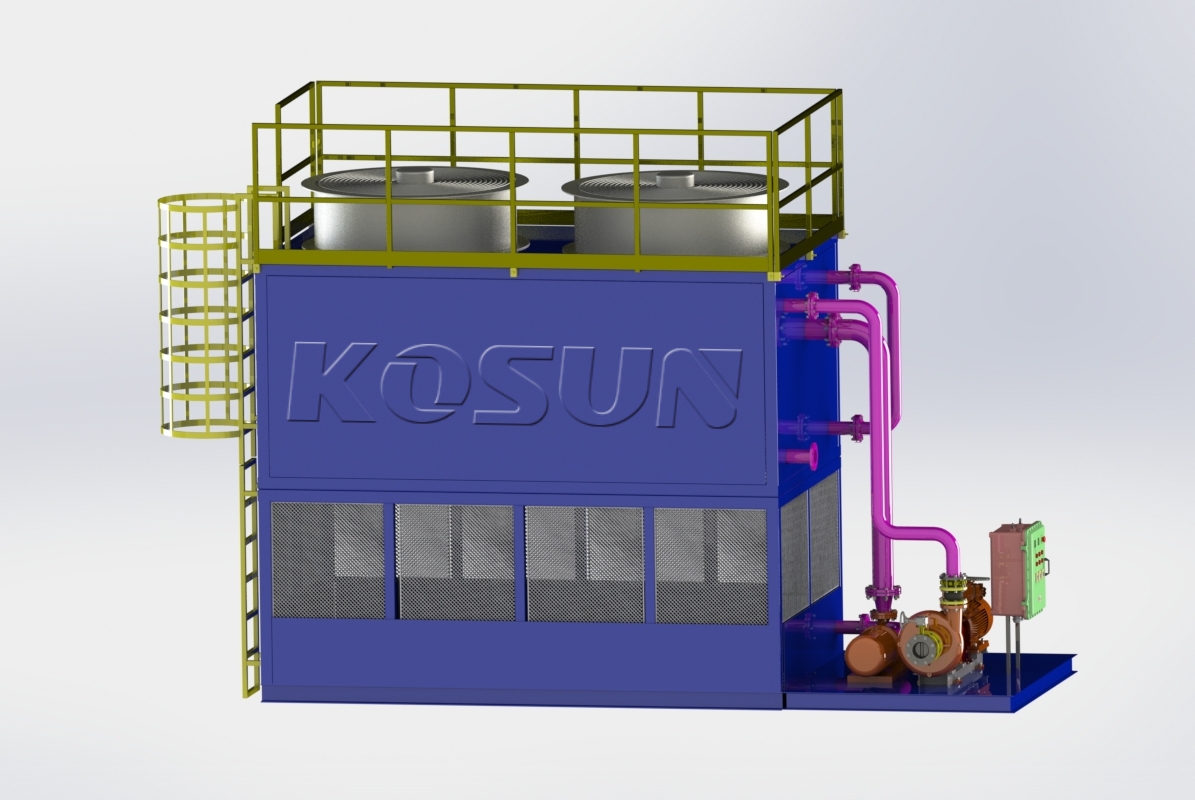

Mud (Drilling Fluid) Cooling System

Liquid Mud Plant (LMP )

Skid-mounted Solids Control System

Arctic Solids Control System

Double track shaker

Mud Cooling System

Drilling Mud Solids Control System

KOSUN Mud Cooling System, HTHP Drilling Safety EnsuredAs global energy demand continues to grow, oil and gas drilling technology is moving towards complex fields such as deep wells, ultra-deep wells, and high-temperature, high-pressure (HTHP) wells. With ...

Necessity of Liquid Mud Plant(LMP) in Modern Engineering ProjectsIn today's pursuit of efficiency and environmental compliance, traditional mud treatment methods are obsolete. Modern engineering projects such as oil and gas drilling, Horizontal Directional Drilling ...

KOSUN KSMR Series Mud Recycling System: Core Equipment for HDD&Trenchless ConstructionHorizontal Directional Drilling Technology Horizontal Directional Drilling (HDD) is a core technology for trenchless underground pipeline laying. A pilot hole is first drilled using a directional drill...

Horizontal Directional Drilling (HDD) TechnologyAddressing the mud problem has become crucial for the continued advancement of HDD technology. Fortunately, alongside technological development, new solutions are emerging. For instance, the Horizontal...

Principles and Optimization of Oily Sludge Reduction TreatmentFor years, Xian KOSUN has specialized in developing technologies for the reduction, harmless treatment, and resource utilization of oily sludge. By continuously integrating field experience with proces...

Efficient HDD Mud Recycling: KOSUN Helps You Reduce Costs and Ensure ComplianceAs urban infrastructure and pipeline networks expand rapidly, Horizontal Directional Drilling (HDD) has become a critical construction method. However, the drilling fluid (mud) used in HDD projects is ...

Shanghai -40m³/h sludge-water separation system1. Project Background The total length of the underground drainage network in the central urban area of Shanghai exceeds 12,000 kilometers. With the arrival of the rainy season, the siltation thickness...

Large-scale ecological lake dredging and treatment projectLarge-scale ecological lake dredging and treatment project Project Background: The Xi an KOSUN Lake dredging and treatment system is designed to address issues such as sediment deposition and water qua...

KD-50 Trenchless sludge-water separation equipmentProject Case Introduction: Application of Russian KD-50 Trenchless sludge-water separation equipment Project Background: With the acceleration of urbanization in Russia and the in...

Kuwait - Landing Oil Sediment Treatment SystemProject Background: Kuwait, as a globally significant oil producer, generates a large amount of oily sludge during the process of crude oil extraction and transportation, posing a severe challen...

Solid control system of ZJ70 drilling rig in TurkmenistanProject Background: Turkmenistan, as an important energy producer in Central Asia, has extremely high requirements for the reliability and environmental friendliness of drilling equipment in the...

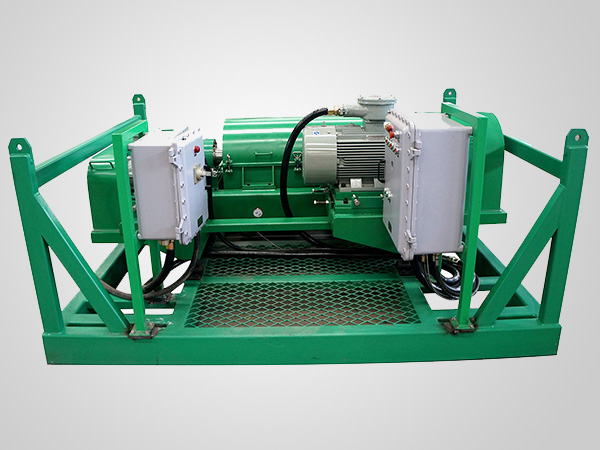

Skid-mounted double pump unit projectThe skid-mounted double pump produced by Xi 'an KOSUN is equipped with an independent diesel engine. The sand pump skid-mounted unit is composed of a generator set, two sand pumps and an inlet manifold...